Assembly Method: Sub-Assemblies

11-10-2022 11:00

Become an expert in the assembly of complex reinforcement elements.

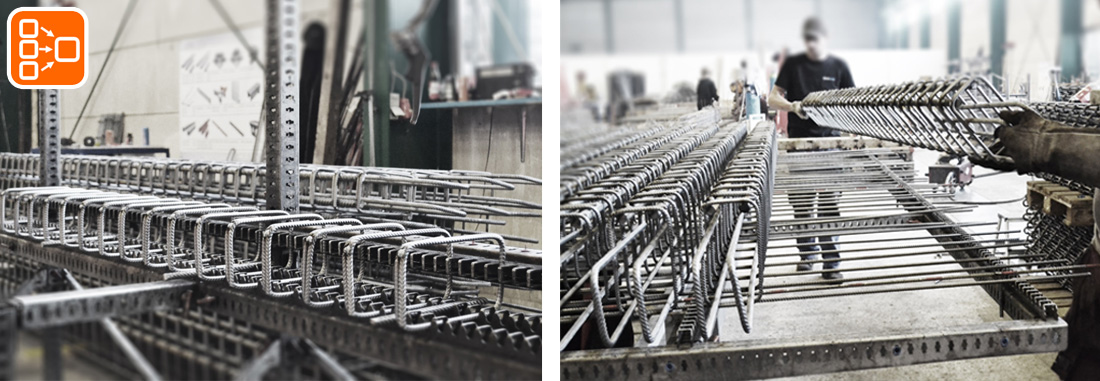

By using the SKEW JIG System, the usage of Sub-Assemblies becomes very interesting, especially when welding reinforcement.

The smaller reinforcement sub-assemblies can be made quickly on smaller ergonomic workstations.

By merging the sub-assemblies, a larger element can be made, as done in industrial assembly lines.

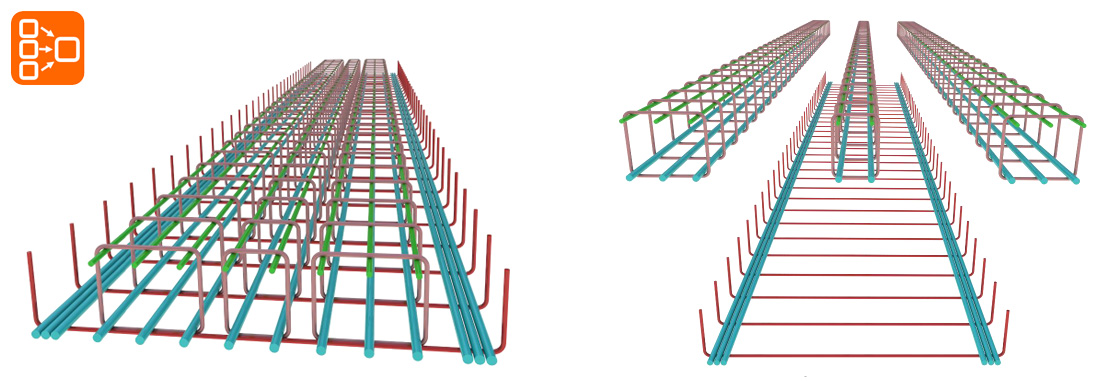

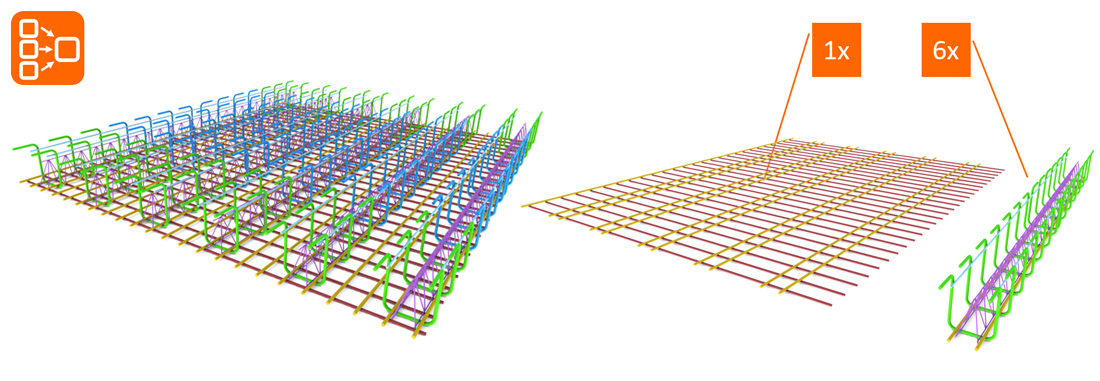

In the example below, the element is split into a base mesh and several sub-assemblies.

The seven building blocks can then be merged to form the final assembly. Six beam-shaped elements can be prefabricated on the SKEW Bench JIG.

The base mesh can be assembled on the Table JIG or can be even prefabricated on a mesh-welding machine.

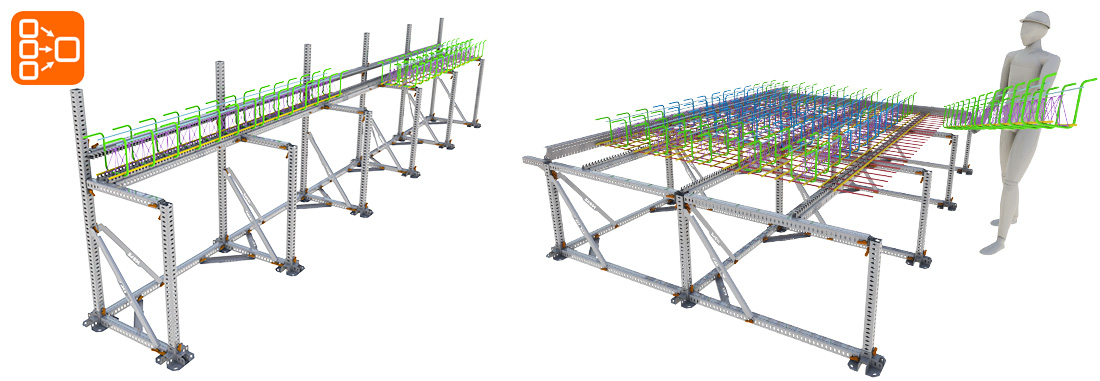

A major advantage is that a lot of the labour can be performed in an ergonomic workspace.

By clever splitting an element, a small production line can be created, allowing the tasks to be straightforward and efficient.

In the pictures below a complex slab is formed from a simple mesh and several beams.

In a traditional assembly method, this slab would be labour-intensive to tie or weld together. The large surface of the slab, in combination with the substantial amount of bars and stirrups result in a large percentage of work that is performed in an unergonomic, awkward position.

By prefabricating the smaller stirrups on a JIG System into beams, most of the work can be prepared conveniently. The beams can be dropped on the bottom layers of reinforcement. Additional rebar is easily added, to finish the complete element.

The grid of the SKEW JIG System allows the rebar sub-assemblies to align properly when being merged.

The 25mm grid is compatible with standard mesh or other reinforcement that is assembled on the JIGs.

By exercising with sub-assemblies, more and more reinforcement will appear to be suitable for this assembly method.

| << | April 2024 | >> | ||||

| Mon | Tue | Wed | Thu | Fri | Sat | Sun |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| 29 | 30 | |||||